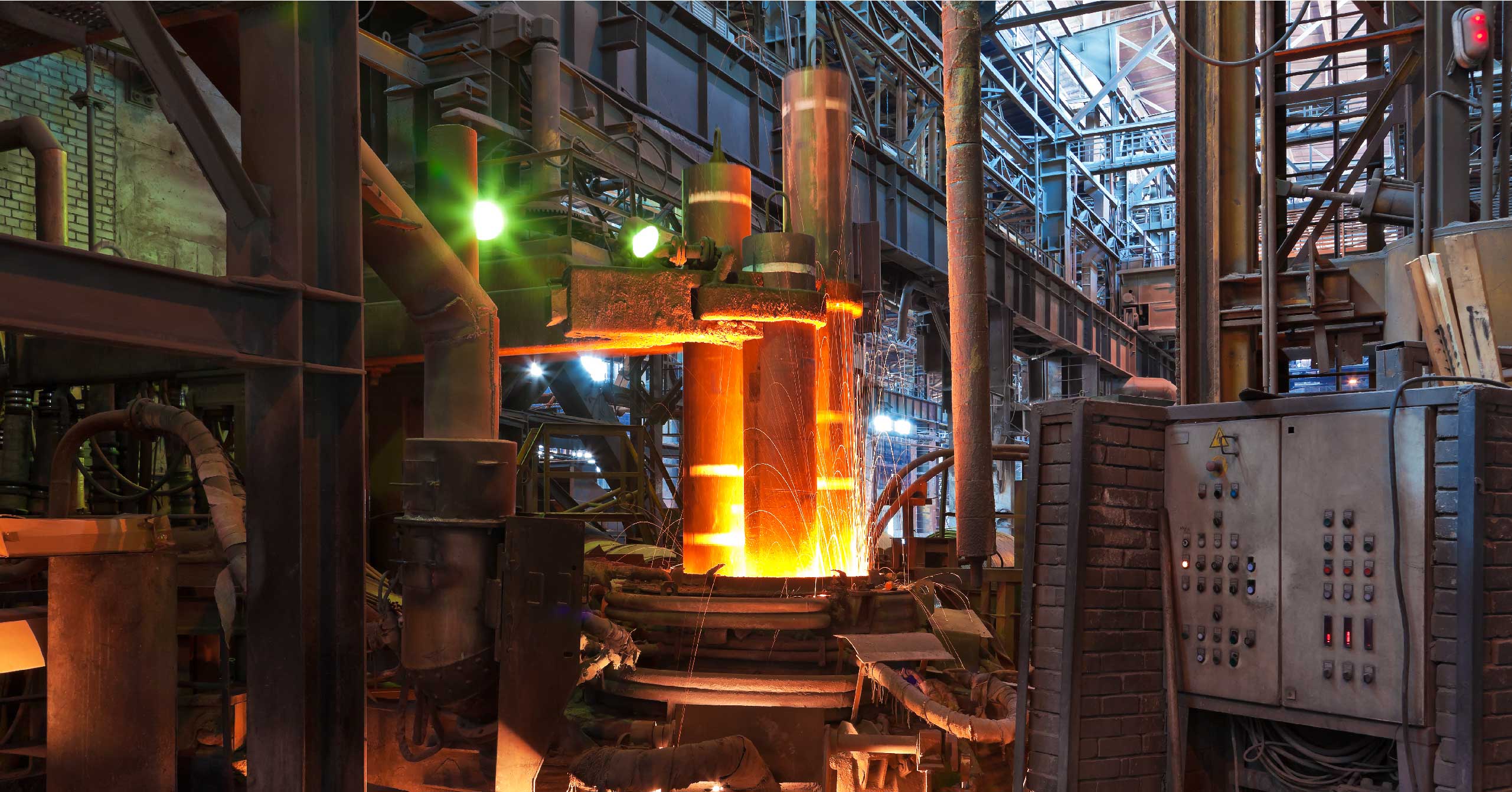

Supercharge Your EAF Performance with Berry Metal’s Chemical Energy Solution

Improve efficiency. Lower operating costs. Increase throughput.

For more than 25 years, Berry Metal Company has been at the forefront of innovation in electric arc furnace (EAF) technology, harnessing the power of its advanced Oxygen Injection Technology. This long-standing expertise has enabled us to continuously refine and optimize its EAF chemical energy packages, resulting in highly efficient and cost-effective solutions for the steel industry. By integrating precision oxygen injection into the EAF process, Berry Metal has developed a solution that enhances combustion, reduces energy consumption, and improves overall process efficiency.

As a result, we have brought to market one of the industry’s most robust and reliable chemical energy solutions—helping steelmakers achieve greater productivity, lower emissions, and reduced operational costs. Berry Metal’s commitment to innovation and quality ensures that its EAF chemical energy packages remain at the cutting edge, providing a vital competitive advantage to steel producers worldwide.

V-Max™ & V-Max1™ Oxy-Gas Burners

Patented “V-groove” construction combined with concave face helps push shrouded oxygen into the natural gas for, promoting better more stable flame at the burner Flame, and tighter lance flame.

- Allows for waterless burner technology when paired with DuraForge™ Box.

- Water-cooled or Waterless design options

- 2- piece design for easy maintenance and lighter design

- Replaceable inserts allow for flexibility to change flow rates

- Insert nozzle angle +/- 3 degrees in any direction from the burner box angle

- Engineered to provide optimum angle, distance, and performance to suit site specific EAF scenarios.

- Most efficient combustion

- Most efficient oxygen delivery to the bath

V-Max1™ Adaptable Burner

- Endless adaptability with flexible sidewall compatibility, direct drop-in replacement design, and expert support

- Seamless integration using modular components that fit into existing systems and enable scalable expansion

- Long-term reliability built for harsh EAF environments, reducing maintenance and minimizing downtime

- Simplicity through innovation with intuitive controls and a modular design that streamlines installation and maintenance

DuraForge™ Box

- Forged Copper Construction with Steel Reinforcement allows for tighter grain structure which makes it tougher that non-forges or cast boxes

- Design allows for steeper or adjustable angles-custom to each furnace

- Multiple custom injection ports can be installed in each unit

- Improved injection efficiency by positioning burner & injectors closer to steel bath

- Outstanding high thermal conductivity resulting in longer life from better cooling of box, burners & injectors

- Use of thermowells with RTDs monitor front face copper temperatures to mitigate opportunities for blowback damage during operation.

- Easily repairable– longer lifespan compared to traditional cast boxes

ECOJet™ Carbon Injectors

- Uses supersonic air stream to deliver carbon media.

- Utilizes less air compared to other designs, but with better penetration.

- Speeds above Mach 1.8 obtained with standard shop air supply

- 30 times greater injection pressure at the slag/metal interface

- Patented radially converging nozzle design entrains the media stream, promoting a tighter media stream, better penetration depth.

- BMC custom engineered solutions that make best use of existing equipment (such as silos, day bins, etc.) or design and build complete systems from the ground up to meet customer needs.

- Unique Air-Assist that fluidizes material to promote better material flow.

- Transporters customized for each client

- Dense flow transport design better allows for a large gradation of material sizing

- Allows for changes Carbon of the Future and today’s carbon options

- Injectors and burners housed in custom DuraForge™ Water-Cooled Forged Boxes to provide optimum protection-enabling injection points to be closer to bath

- Designed to maximize existing equipment and available space

- Custom to fit the desired material storage requirements

- Customized HMI for operators and maintenance personnel

Additional EAF Products & Services

Dynamic Carbon & Lime Injection Solutions

Carbon injection is a crucial process in EAF steelmaking, significantly improving the efficiency and quality of production. By enhancing foamy slags through effective carbon injection practices, steelmakers can achieve a range of benefits, including:

- Reduced Power On Time

- Lower Energy Consumption

- Improved Yield

- Refractory Savings

- Enhanced Electrode Consumption

Berry Metal Company is a leader in engineering and manufacturing carbon injection solutions, providing expertise across all three methods. Our products are designed to suit a variety of furnace shell designs, ensuring optimal performance in all steelmaking environments. We specialize in designing, supplying, and repairing carbon injectors of any size to meet specific requirements.

Additionally, BMC offers a new and improved air-assisted carbon injection lance assembly with a specialized carbon nozzle, further enhancing efficiency and effectiveness.

While relatively new in EAF steelmaking, lime injection is gaining traction as a valuable process for many steel producers. Traditionally, lime was charged through scrap buckets or top-charged via bags or conveyors. However, injecting Dolo and HiCal lime through specially designed sidewall lances or burners has resulted in several key advantages, such as:

- Reduced Lime Consumption

- Improved Slag Flexibility

- Enhanced Environmental Safety

- Reduced Lime Waste in the Bag House

As steelmakers strive for more efficient and sustainable operations, lime injection is proving to be a highly effective solution in optimizing the EAF process.

Berry Metal’s expertise in both carbon and lime injection systems ensures that your EAF steelmaking operations are optimized for maximum efficiency and minimal environmental impact. From carbon injection lances to lime injection burners, we provide the tools you need to improve performance and reduce costs. For more information about our carbon and lime injection solutions, contact Berry Metal today to learn how we can help you improve your EAF operations.

Panels

DuraForge™ Forged Copper Panels

Our patented forged copper construction offers superior water cooling capabilities compared to traditional cast designs. The benefits of this innovative approach include:

- Enhanced Water Flow: The forged construction allows for better water circulation, improving cooling efficiency.

- Tighter Copper Grain Structure: This structure promotes better cooling and reduces wear, ensuring longer-lasting performance.

- Front Face Cooling Optimization: Our design specifically targets the front face cooling for maximum efficiency.

- Slag Cup/Bar Design: Unlike traditional pipe panels, our slag cups/bars are designed to handle accretion more effectively, improving overall furnace performance.

UltraLife® Cast Copper Panels

The internal pipe coil cooling system is a reliable, long-lasting solution designed to contain water and deliver optimal cooling performance. With customizable panel sizes and shapes, it offers design flexibility for various applications. Featuring deep slag pockets, intertwined cooling circuits, and efficient fin panels, it ensures uniform cooling distribution and enhanced heat transfer. Additional components like the slag door tunnel and sidewall panels further improve cooling efficiency. Ideal for demanding environments, this innovative system guarantees consistent and efficient cooling performance.

Customized Design & Construction for Furnace-Specific Needs

We offer customized solutions designed to address unique challenges faced by each furnace. Our designs are tailored to meet your specific furnace requirements, ensuring optimal performance and durability:

- Custom Solutions for Furnace Problem Areas: Whether dealing with arc strikes or hot spots, our designs are tailored to resolve furnace-specific issues.

- Furnace-Specific Designs: Our solutions are designed to fit the unique needs of your furnace and can be adapted to existing openings.

- Targeted Problem-Solving: We create designs that directly address the specific challenges faced by your furnace, ensuring reliable and efficient operation.

Robust Construction & Enhanced Repairability

Our forged copper construction with steel reinforcement ensures exceptional durability and repairability, making it the ideal choice for high-performance furnaces:

- Superior Forged Copper Construction: The tighter grain structure in our forged copper provides better wear resistance and longer product life compared to traditional pipe panels.

- Lower Repair Costs & Reduced Downtime: Our construction is designed to be more durable, resulting in fewer repairs and less downtime during maintenance periods.

- Improved Safety: The robust design minimizes the risk of water leaks, enhancing safety during operation.

- Reliable Welding: Our expertise in welding copper to copper and steel to copper ensures strong, leak-resistant joints, enhancing overall reliability.

- Long-lasting Durability: The welded connections are designed to withstand high temperatures and stresses typical in furnace environments.

- Enhanced Structural Integrity: Our welding ensures the structural integrity of the components, resulting in fewer failures and improved furnace performance.

With our focus on forged copper construction, customized designs, and robust repairability, Berry Metal Company provides the most reliable and cost-effective solutions for furnace water cooling systems. Our expertise in welding and construction ensures the longevity and performance of every product.

Additional EAF Components

- Degas Lance Tips: Designed for precision and efficiency, our degas lance tips ensure optimal performance in the degassing process of steel production. They are engineered to minimize wear and maximize the lifespan of your equipment.

- Auto Taphole Sanding Systems: eliminates employees’ exposure risk to liquid metal when performing maintenance on the sanding system. The systems are installed completely off the tilt platforms, so no equipment is mounted on the furnace shell. Maintenance can be performed without any interference to EAF Operations, while keeping all EAF personal at a safe, clear distance.

- Inspection Systems: Our advanced inspection systems are essential for maintaining high standards of quality control. With cutting-edge technology, these systems offer precise monitoring and diagnostics to ensure the longevity and performance of your equipment.

- Copper Tips for EAF Lances: Our copper tips provide exceptional durability and heat resistance. These tips are designed to withstand the extreme conditions of steel production, offering superior performance and reliability.

Berry Metal Company is committed to delivering innovative, durable, and cost-effective products to enhance the efficiency of your operations. Our expertise and commitment to quality make us a trusted partner in the metal production industry.

EAF Repair Capability

Berry Metal Company brings over 70 years of experience to the table. We specialize in providing high-performance solutions, including expert repairs, innovative product designs, and exceptional customer service to ensure your operations run smoothly. Our comprehensive range of services includes:

Timely, First-Class Repairs

Berry Metal offers fast, efficient repair services to meet even the tightest deadlines. Our repair capabilities are designed to minimize downtime and ensure your equipment is back to optimal performance in the shortest time possible. Whether it’s an urgent fix or a planned maintenance task, we’ve got you covered.

Outstanding Technical Service

Our technical experts provide in-depth support to optimize the performance and reliability of your equipment. From troubleshooting to guidance on product performance, we ensure that your equipment operates at peak efficiency.

Specialized Delivery Services

We offer delivery services using Berry Metal Company trucks, ensuring safe and reliable transportation of your parts and products directly to your facility. Our dedicated fleet ensures timely, secure deliveries, making logistics more convenient for you.

Comprehensive Product Failure Analysis

We conduct a complete product failure analysis, helping you identify underlying issues and improve the performance of your products. Whether it involves repair or replacement, our team provides actionable insights to extend the lifespan and reliability of your equipment.

Convenient Repair Locations

Berry Metal operates convenient repair locations in Harmony, PA, La Porte, IN, and Bay Minette, AL, strategically located to support our nationwide clientele with accessible service and support.

High-Quality Welding Services

Our welding services are second to none, offering the highest quality welds on fabricated parts and supplied component parts. We utilize state-of-the-art welding techniques to ensure precision and consistency in every job.

- All our welders are certified under ASME Section IX standards.

- We provide x-ray quality welds that meet exact customer specifications and tolerances.

State-of-the-Art Manufacturing Equipment

Berry Metal invests in cutting-edge manufacturing equipment to ensure high-quality, precise fabrication and welding. This technology enables us to handle materials such as steel, stainless steel, aluminum, nickel, Inconel, bronze, and copper with precision and efficiency.

Fabricated Water-Cooled Panels and Coils

We specialize in fabricated water-cooled panels and coils made from copper or steel, designed to perform efficiently in demanding industrial environments. These panels are crucial for cooling applications, ensuring the longevity and safety of equipment used in high-temperature settings.

Water-Cooled Copper Burners – Design & Repair

Our team offers design, repair, and reconditioning services for water-cooled copper burners, ensuring they operate effectively and efficiently under high-stress conditions. We work with you to create customized solutions tailored to your specific requirements.

Copper Panel Repair, Reconditioning, and Rebuild

We provide expert repair, reconditioning, and rebuilding of copper panels, offering a cost-effective solution to restore your equipment to its optimal condition. Our team uses precision techniques to enhance performance and extend the lifespan of your copper components.

Water-Cooled Oxygen Lance Design and Repair

Berry Metal designs and repairs water-cooled oxygen lances, key components in steel production. Our lances feature several innovative advantages:

- Double O-ring design: Protects against the intermixing of oxygen and water, ensuring maximum safety and efficiency.

- Internal slip joints: Allow for thermal expansion and contraction, preventing internal stress and damage.

- Modular design: Makes inspection, repair, and maintenance simpler and more efficient, reducing downtime and improving longevity.