Berry Metal is driven to develop new technologies to help iron and steelmakers.

Berry Metal Company is bringing cutting-edge technology and equipment to the iron and steel industries. We are making additional technological innovations available to our customers, helping companies win within an environment of change. Berry Metal is creating and developing the conditions for manufacturers in the iron and steel industry to identify and implement high quality products that benefit them immediately. Instant positive results via breakthrough technology – Berry Metal is bringing this to customers, to help them succeed in a new world of competitiveness and performance.

- Achieve higher productivity at lower cost and improve safety

- Meet today’s greener steelmaking goals and future targets

- Reduce energy consumption and utilize new sources of raw materials and energy.

Our Comprehensive Engineering Capabilities

- Advanced 3D Modeling & Automation: Cutting-edge design solutions with seamless automation for optimized production.

- 2D Manufacturing Drawings: Precise and detailed drawings that meet industry standards for reliable manufacturing.

- Onsite Technical Support & Construction Management: Expert guidance and oversight to ensure smooth project execution and timely completion.

- ANSYS Computational Fluid Dynamics (CFD): Advanced CFD simulations for accurate flow analysis and system optimization.

- ANSYS Finite Element Analysis (FEA): Robust FEA tools for structural integrity and performance analysis of your designs.

- Custom Pneumatic Transport Systems: Tailored designs for efficient transportation of alloys and other materials.

- Custom Lance, Valve, Burner, Box & Housing Designs: Specialized equipment designs that meet your exact specifications and improve system performance.

- Field Services for Performance Evaluation: Comprehensive on-site evaluations to ensure optimal system functionality.

- Innovative Repair Techniques & Procedures: State-of-the-art repair solutions that extend equipment life and enhance reliability.

- Process Improvement Analysis & Studies: In-depth process assessments to identify opportunities for efficiency and cost savings.

- Equipment Inspection & Technological Upgrades: Thorough inspections aimed at improving service life, simplifying maintenance, and reducing energy consumption.

- E&A Development – Design & Programming: Expertise in electrical and automation systems design, including programming for seamless integration.

- PLC Engineering & Cabinet Construction: Custom PLC solutions and expertly constructed control cabinets for enhanced system performance.

- HMI Screen Creation & Development: User-friendly HMI screen designs that streamline operations and improve control.

By leveraging these capabilities, we ensure optimized systems, increased productivity, and innovative solutions tailored to your specific needs.

Our team is composed of highly skilled professionals with expertise across various engineering and technology domains, including:

- Licensed Professional Engineers (PEs)

- Certified Project Management Professionals (PMPs)

- Electric Arc Furnace (EAF) Applications Engineers

- Basic Oxygen Furnace (BOF) Applications Engineers

- Blast Furnace Applications Engineers

- Software Engineers Specializing in Allen Bradley & Siemens PLC Control Systems

With a diverse skill set, we deliver cutting-edge solutions for industrial and manufacturing sectors, ensuring efficiency, safety, and innovation in every project.

Latest Innovations: New Developments and Advancements

Electric Arc Furnace

- Auto Taphole Sanding Systems w/ Pneumatic Sump Cover (Fall 2023)

- ECOJet™ Carbon Injector – Best in class sidewall carbon injector, allowing for optimal injection performance of carbon and carbon substitutes, utilizing minimal outside air to be added to the furnace, limiting excess CO2 creation

- Pneumatic Carbon Injection System – Silo to Furnace Sidewall (Fall 2024)

- High Temp Camera Inspection System – High temp camera in BMC WC Housing allowing for full shell ID scan between heats from the pulpit to assist in “no man on the deck” safety protocols. (Trial Ongoing)

Basic Oxygen Furnace

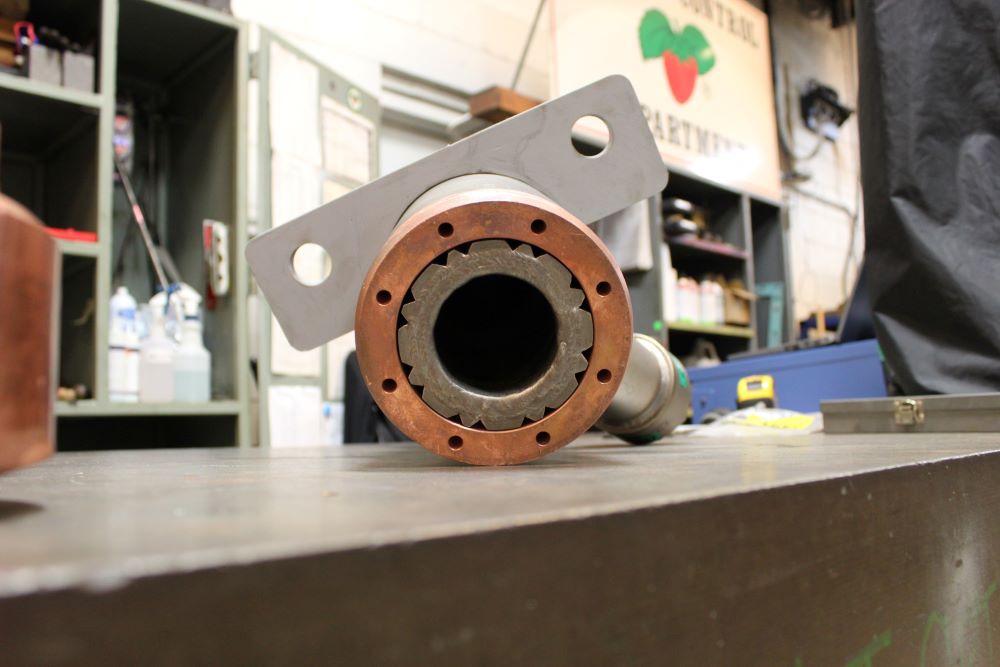

- DuraForge™ Tip – One-Piece Forged Copper Tip with Industry Best Life (Spring 2024)

- Cyclone™ Tip – One-Piece Forged Copper Tip with angular nozzles to promote better bath stirring & mixing during operation. (Summer 2024)

Expert Repair & Technical Services

At Berry Metal, we take pride in our ability to deliver a wide range of comprehensive equipment repair and technical services tailored to keep your production processes running without interruption. With years of industry experience, our expert team is equipped to quickly identify the root cause of any equipment breakdown, providing you with fast and reliable solutions. Berry Metal operates convenient repair locations in Harmony, PA, La Porte, IN and Bay Minette, AL, strategically located to support our nationwide clientele with accessible service and support. Through advanced diagnostic tools and deep technical knowledge, we are able to assess and address any issues that may arise with your machinery.

Our engineers then develop and implement the most effective, customized solutions to restore your equipment to optimal performance. Whether it’s repairing critical components, upgrading outdated systems, or conducting preventative maintenance, we ensure that every repair is done with the highest standards of precision and care.

Comprehensive, Cutting-Edge Services:

- On-Site Troubleshooting & Root Cause Analysis

- Project Management & Turnkey Project Engineering

- Onsite Supervision & Maintenance

- Predictive & Preventative Equipment Inspections

- Emergency & Crisis Management Solutions

Specialized Equipment Repairs:

- EAF Repairs: Sidewall Boxes/Panels, Burner, Door Lance, Slag Door, Preheater, Injection Systems

- BOF/QBOP Repairs: Lance, Carriage, Hood Plug Repairs

- Blast Furnace Repairs: Valve Repairs, Hydraulic Control Stand Repair & Upgrade

- LMF/AOD/Degasser/Ladle Stations Repairs: Lance Repairs, Carriage Preventative Maintenance & Repairs

- Reheat Furnace Repairs: Burner Repairs/Reconditioning, Entry/Exit Door Maintenance

- Material Handling Repairs: Conveyor, Table Roller, Shaft, Bearing, Mandrel/Coiler Repairs

- Rolling Mill Repairs: Guide, Roll, Pinch Roll

Additional Repair Services:

- Cast House Equipment Repairs

- Pneumatic Conveyance & Conveyor Repairs

- Control Stand & Boost Chamber Repairs

By partnering with Berry Metal, you benefit from minimized downtime, enhanced productivity, and a reduction in the costs associated with equipment failure. We focus on maximizing the efficiency of your steel making operations, which in turn helps lower operating costs and improve your product quality.